Zahar Bod Success Story

Country: Romania

Industry: Food

Products: Robot, Gripper, Base frame, Automation & Safety

The challenge:

The automatic palletizing of the 50 Kg sugar bags, for a 8 bags per minute productivity.

The solution:

After analyzing the input information and after talking to the beneficiary, we proposed the following equipment:

- A belt conveyor, for the collection of the bags from the existing production line

- A roller conveyor, in order to allow the collection of the bags by means of the gripper

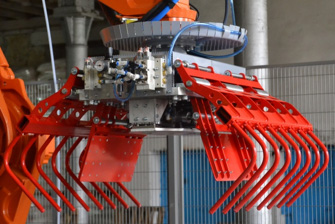

- An ABB IRB 660 robot, with metallic base frame and an EvoGrab claw gripper

- A motor driven roller conveyor and a gravity roller conveyor, for the pallets

- Automation, build around a Compact Logix Allen Bradley PLC

- Safety systems, consisting in a protection fence, safety barriers, interlocks and emergency-stop buttons.

The results:

- A cost reduction by using a single operator for palletizing (initially, there were 4 operators)

- A 30% productivity increase for each shift and the possibility to work in multiple shifts

- An improvement of the work conditions and of the operators’ safety

Project Management: Despite a very tight deadline, the system was designed, developed and installed, one day earlier than the contract term.